Filler Metal F Number

This article provides information about F number in WeldingProcedure Specification based on the requirement of ASME Code Section IX.

- Aws Filler Metal Classifications

- Filler Metal F-no 6

- Tgx Filler Wire F Number

- Er320 Filler Metal F Number

- Filler Metal F Numbers

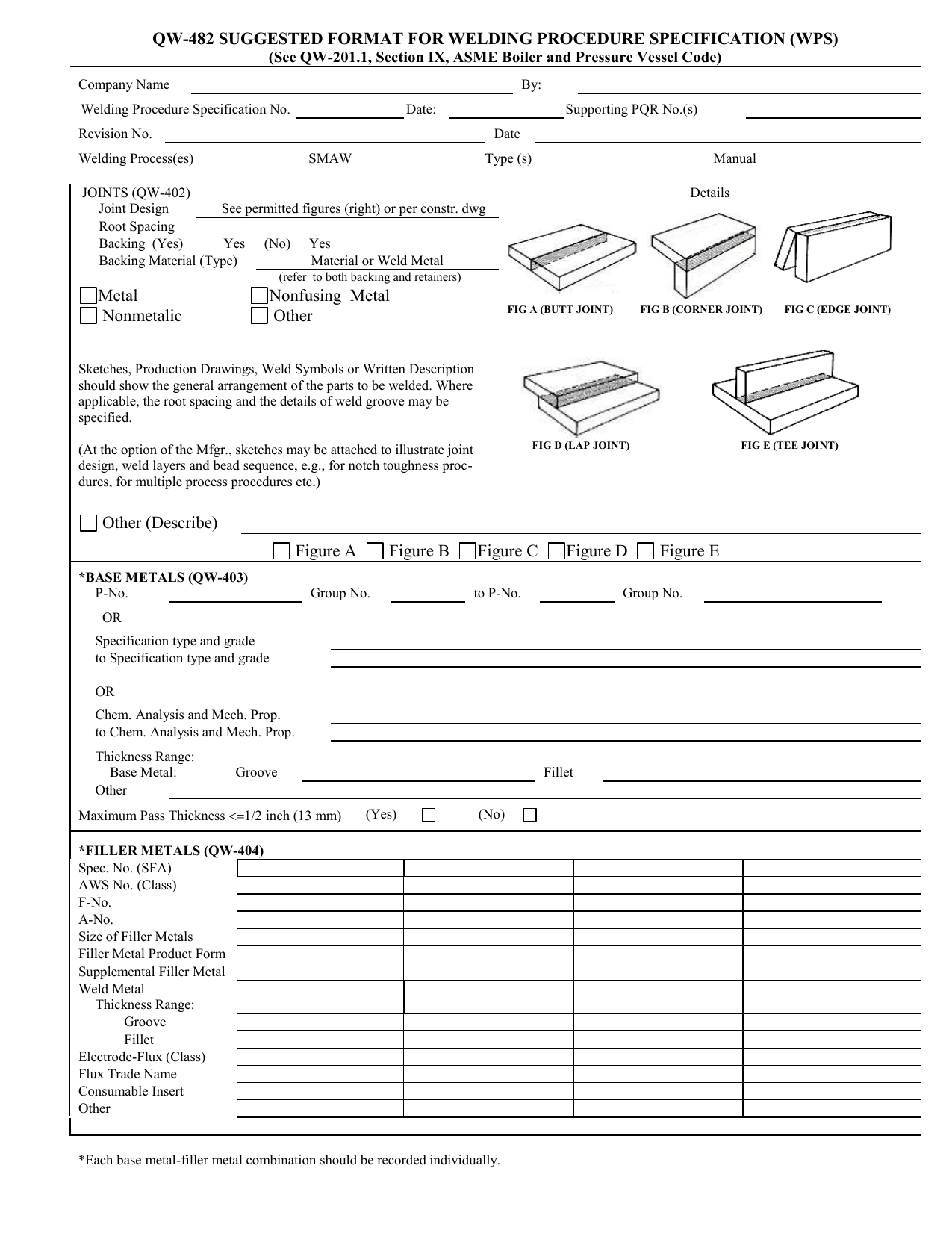

The F number grouping of filler metals refers to theirsimilarity on their usability characteristics. The usability determines theability of a welder to deposit a sound weld metal with a certain filler metal.

The F number is essential variable in the most weldingprocess for welding procedure specification and also in welding performancequalifications. Like the P number, the Fnumber designed to reduce the number of procedure qualification and weldingperformance qualification.

Where can I find a chart depicting F numbers for Stainless steel GTAW wire. I want to verify the ER308, Er308L, ER316, ER316L, Er309, ER309L and ER304, Er304L, ASME Filler Metal Classifications - ANSI (standards) Code Issues - Eng-Tips. Prolonged temperatures in excess of 1500 f. Special alloys and tempers are often required to overcome this problem. Contact alcotec for assistance in alloy and temper selection when elevated temperature service is a concern. Alcotec wire corporation 2750 aero park dr., traverse city, mi u.s.a. 1-800-228-0750 fax 231-941-9154.

Aws Filler Metal Classifications

I have seen some many people confusing about F number andbelieving the F number is grouping for the similar chemical composition. Thisis not true, and F number is only about of usability characteristics such aswelding position.

F number in Welding Procedure Specification

Filler Metal F-no 6

Table QW-432 in ASME Code Section IX provides the list of Fnumbers. Any change from one F number in welding to the other F number is essentialvariable in the welding procedure specification. The changing from one F numberto other F number is a little bit different in welding performancequalification. The essential variable tables in welding performancequalification (QW-352 thru 357) refer you to the QW-433 for the range of qualification.

Tgx Filler Wire F Number

For example, a welder qualified with F number 4, he alsowill be qualified on the F numbers 1, 2 and 3.

Some contractors use the essential variable tables (QW-352thru 357) to minimize their costs. For instance, they might test the welder forstainless steel material by using carbon steel material. Consider the actualproject material is stainless steel and you do not want to waste stainlesssteel material for testing. You ask the welder to weld in carbon steel materialbut with stainless steel filler metal. Based on the essential variable table Pnumber 1 (Carbon Steel) qualifies P 8 (Stainless Steel), and the F number isthe same. So you qualify your welder for stainless steel material by usingcarbon steel material but stainless steel filler metal.

Er320 Filler Metal F Number

When you have a welder or welding operator with a certainqualification, and you want to use him in some other job, you need to see ifall the variables in the essential variable table confirm his qualification forthe new job. Each of the item in the table has veto right, if 6 out of 7 is Ok,but only 1 of them is not meeting the requirements, and then you cannot usethat welder in the new job and you need to re-qualify him by the new test.

The ASME Section IX Training Course is 2 days video training course and available online and the student that successfully pass the exam, receive I4I academy certificate with 16 hours training credit.

Filler Metal F Numbers

Related Links:

Nonessential Variables, Supplementary Essential Variables, A number in WPS

Did you find this article useful? Click on below Like and G+1 buttons!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.